|

|

friction measurement devices to the International Friction Index (IFI).

Nippo Ltd.'s Products

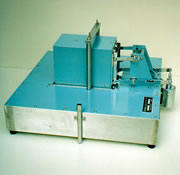

Dynamic Friction TesterASTM E-1911-98

The

D.F. Tester is an easy-to-use portable instrument to measure dynamic

coefficient of friction. The physical principles involved in the

measurement of friction are straightforward, but their implementation

for practical purposes can solve a wide range of problems. The D.F.

Tester is an instrument which can determine the physical properties

needed by different industries as it can measure coefficient of friction

under various conditions. For example in the case of skid resistance

which is closely related to the performance of automobiles, there was no

such instrument which could directly measure the coefficient of

friction, although there were some measuring instruments that correlate

to it. Many instruments have been introduced which measure slipperiness

but none are as reliable and easy to use with minimal interference with

traffic as the D.F. Tester. This device is also contained in the FHWA's (Federal Highway Administration) Measuring Instrument Guide.

FEATURES

MEASURING PRINCIPLE

The tire rubber is pressed against the road surface with a force W, and a horizontal force F is applied to move the rubber with a speed V. µ = F/W (1) By holding W constant and substituting K (a constant of proportionality) for 1/W in equation (1), we obtain: µ =K * F (2) Thus, the coefficient µ varies in direct proportion to F. In the D.F. Tester, the tire rubber is fitted to three rubber sliders on the underside of a horizontal rotary disk. The disk bears on the road surface supported by the three rubber pad on the sliders under a constant load W perpendicular to the surface, and rotates at a speed where the tangential velocity at the location of the sliders is V. The force F required to overcome the dynamic friction is measured, and the linear speed V of the slider is determined from the rotary speed of the disk. How to read the measured data.

USE

D.F. Tester Proper :

Controller : ACCESSORIES

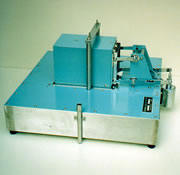

Dynamic Friction Tester S-Type

The D.F. Tester S-Type is designed to measure coefficient of friction on pedestrian surfaces while the D.F. Tester was designed to measure the dynamic coefficient of friction on paved road surfaces. The S-Type D.F. Tester can measure the static coefficient of friction of sidewalks, promenades, amusements, floor surfaces of buildings, gymnasiums, etc. and the dynamic coefficient of friction at speeds from 0 to 15 km/h. This instrument has been developed considering bio-dynamics standards which apply to anti-slipperiness testing devices for pedestrians. It is designed based on the principle of the D.F. Tester, to be portable and operator independent. Also, the coefficient of friction of a material on a surface can easily be measured by changing the rubber (on the rubber slider) to the desired material (the material of a shoe sole, for example). Measurement is possible even if the subject surface has slight unevenness, joints or bevels. The results can be read on site upon completion of measurement as the coefficient of friction at each speed is graphically recorded in a continuous spectrum on the X-Y Plotter. FEATURES

ANALYSIS How to read the measured data.

USE Sidewalks, pavements, floor surfaces of buildings, sports facility floors, etc.

SIZE and WEIGHT D.F. Tester Proper : Controller :

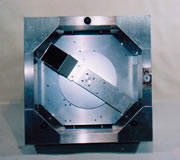

Circular Track Texture MeterASTM E2157-01

The C.T. Meter (Circular Texture Meter) is a road surface macrotexture profiler, in which a CCD (Charged Coupled Device) Laser Displacement Sensor is used. It is designed to measure on the same circular track on which the D.F. Tester measures the dynamic coefficient of friction. There are various methods to characterize road surface macrotexture profiles. The C.T. Meter reports the MPD (Mean Profile Depth) and the RMS (Root Mean Square). The IFI (International Friction Index) can be computed using the C.T. Meter in combination with the D.F. Tester. This instrument is also contained in the FHWA's (Federal Highway Administration) Measuring Instrument Guide.

SPECIFICATIONS:

FEATURES:

The number of samples per one rotation is

1,024 (892 mm) which is divided into 8 segments for the computation of

each MPD and/or RMS. Analysis of the individual segments can be

performed to examine the profile parallel to the The displacement sensor for this instrument is a CCD which is mounted on an arm that rotates at 80 mm above the surface in a circumference of 142 mm radius. The arm is driven by a D.C. Motor at a tangential velocity of 6 m/min. The CCD is sampled 1,024 times per revolution providing a sample spacing of 0.87 mm by an A/D converter. The data are recorded in memory in a notebook computer. The data are segmented into eight 111.5 mm arcs of 128 samples each. The computer software computes the MPD and/or the RMS of each segment. Optionally the MPD and RMS can be computed for the middle 100 mm of each segment. USE Sidewalks, pavements, floor surfaces of buildings, sports facility floors, etc.,

SIZE and WEIGHT C. T. Meter : With Carrying Case :

|

Nippo,

Ltd., established for three decades in the East, is now expanding to

Europe, and we are excited to be part of its expanding network. It

specializes in stationary friction and texture measuring devices that

are known throughout the industry for their quality and durability. The

Dynamic Friction Tester and the Circular Track Meter are rapidly

becoming the de-facto calibration pieces for agencies to standardize

their

Nippo,

Ltd., established for three decades in the East, is now expanding to

Europe, and we are excited to be part of its expanding network. It

specializes in stationary friction and texture measuring devices that

are known throughout the industry for their quality and durability. The

Dynamic Friction Tester and the Circular Track Meter are rapidly

becoming the de-facto calibration pieces for agencies to standardize

their